Supply Chain Revolution: Unlocking The Future Of Global Trade

Alright folks, let's dive straight into the heart of modern business operations. In today’s fast-paced world, the term "supply" isn’t just a simple word—it’s a powerhouse driving economies, shaping industries, and transforming how businesses operate. Whether you’re running a small local shop or a global corporation, understanding supply is no longer optional; it’s essential. So, buckle up because we’re about to unravel the complexities and opportunities hidden within this critical concept.

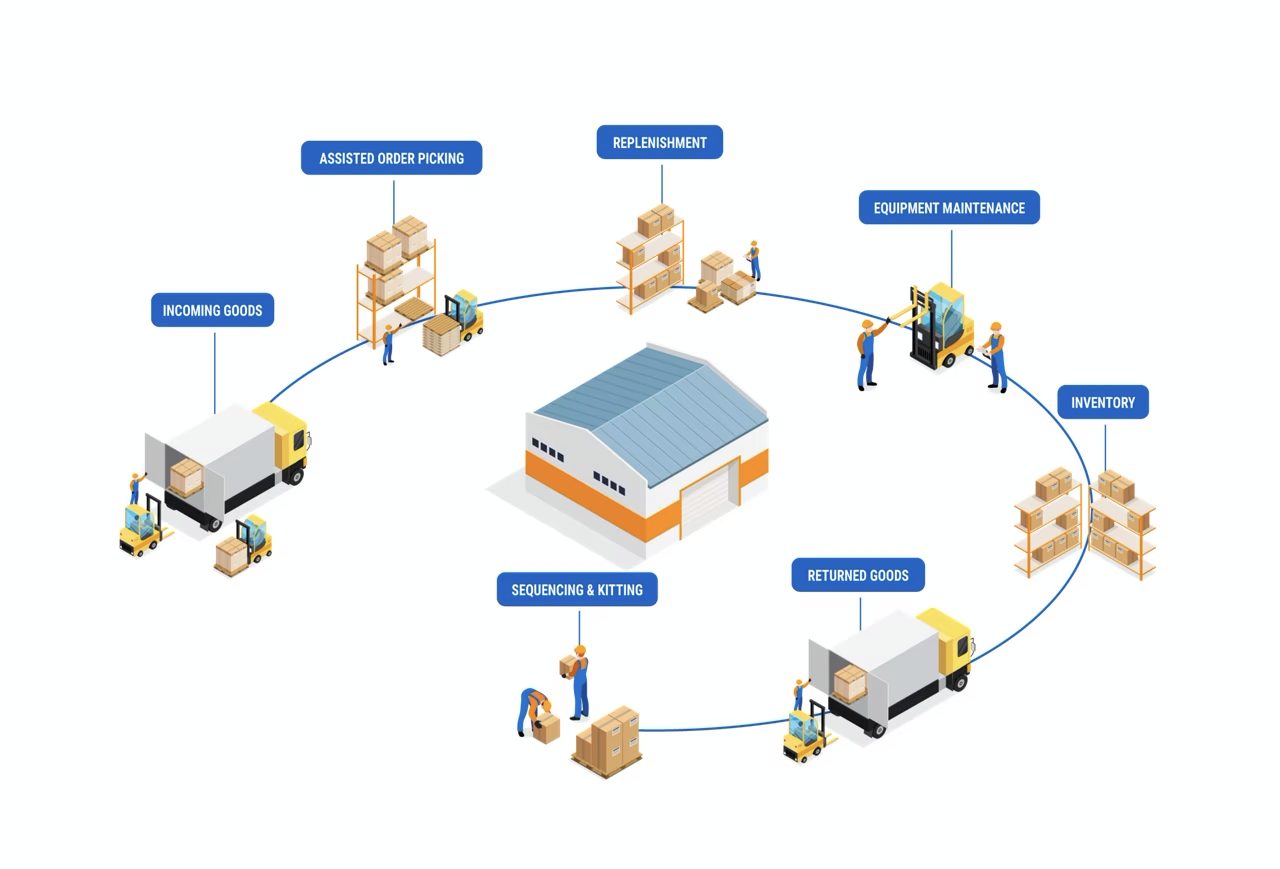

Now, when we talk about supply, we're not just referring to the goods sitting on a warehouse shelf or the raw materials arriving at a factory. It's an intricate web of processes, technologies, and relationships that ensure products get from point A to point B efficiently. And let me tell you, this isn’t your grandpa’s supply chain anymore. The game has evolved, and so must our understanding of it.

But why does supply matter so much? Well, it’s simple. A well-oiled supply system means happier customers, lower costs, and a competitive edge in the market. On the flip side, a poorly managed supply can lead to delays, increased expenses, and dissatisfied clients. So, whether you're a business owner, a logistics expert, or even a curious consumer, knowing the ins and outs of supply is crucial. Let’s explore this fascinating world together!

What Exactly is Supply?

Let’s break it down. At its core, supply refers to the availability of goods or services in the market. But it’s much more than just having inventory on hand. It’s about ensuring the right product is in the right place at the right time, all while maintaining quality and cost-effectiveness. Think of it as a symphony where every instrument plays a vital role in creating harmony. If one part falters, the whole system can fall apart.

Supply isn’t just about physical goods, either. In today’s digital age, services play a massive role too. From cloud computing to online customer support, the concept of supply extends far beyond traditional manufacturing. And with the rise of e-commerce and global trade, the importance of a robust supply system has never been greater.

Key Components of Supply

1. Raw Materials

Every product starts somewhere, and that somewhere is usually raw materials. These are the building blocks of supply, the foundation upon which everything else is built. Whether it’s timber for furniture, steel for construction, or silicon for tech gadgets, raw materials are the lifeblood of production. But sourcing these materials isn’t always straightforward. Fluctuating prices, geopolitical tensions, and environmental concerns can all impact availability and cost.

2. Manufacturing

Once the raw materials are in place, it’s time to turn them into something useful. Manufacturing is where the magic happens, where raw materials are transformed into finished products. This process involves a variety of steps, from design and prototyping to assembly and quality control. And with advancements in technology, such as automation and AI, manufacturing is becoming more efficient and precise than ever before.

3. Distribution

Alright, so you’ve got your shiny new product ready to go. Now what? That’s where distribution comes in. It’s the process of getting products from the factory to the end consumer. This might involve warehouses, transportation networks, and retail outlets. And with the growth of global trade, distribution has become increasingly complex, requiring sophisticated logistics and supply chain management.

Understanding Supply Chain Management

Supply chain management (SCM) is the backbone of modern supply operations. It involves coordinating and managing all activities involved in sourcing, procurement, conversion, and logistics management. The goal? To create value and build a competitive infrastructure that meets customer demands. SCM is all about efficiency, effectiveness, and adaptability. And with the ever-changing market dynamics, staying ahead of the curve is crucial.

One of the biggest challenges in SCM is balancing supply and demand. Too much supply can lead to excess inventory and increased costs, while too little can result in missed sales opportunities and dissatisfied customers. That’s why data analytics and predictive modeling are becoming indispensable tools for supply chain professionals. By leveraging these technologies, businesses can make informed decisions and optimize their operations.

Technological Advancements in Supply

1. Internet of Things (IoT)

The Internet of Things (IoT) is revolutionizing the way we manage supply chains. By connecting devices and sensors, businesses can monitor inventory levels, track shipments, and gather real-time data. This not only improves visibility but also enhances decision-making capabilities. For example, a retailer can automatically reorder stock when inventory levels drop below a certain threshold, ensuring they never run out of popular items.

2. Artificial Intelligence (AI) and Machine Learning

AI and machine learning are transforming supply chain operations by enabling predictive analytics and automation. These technologies can analyze vast amounts of data to identify patterns and trends, helping businesses forecast demand more accurately. They can also automate routine tasks, freeing up human resources for more strategic activities. The result? Increased efficiency, reduced costs, and improved customer satisfaction.

3. Blockchain Technology

Blockchain is another game-changer in the world of supply. By providing a secure and transparent way to record transactions, blockchain can enhance trust and accountability throughout the supply chain. It can also streamline processes by eliminating the need for intermediaries, reducing costs, and increasing speed. Whether it’s tracking the origin of food products or verifying the authenticity of luxury goods, blockchain has the potential to revolutionize the industry.

Challenges in Supply Chain Operations

Despite all the advancements, managing supply isn’t without its challenges. Global events, such as pandemics, natural disasters, and geopolitical tensions, can disrupt supply chains and create bottlenecks. Additionally, rising labor costs, environmental regulations, and cyber threats are all factors that businesses must contend with. But challenges also bring opportunities, and those who adapt and innovate will emerge stronger.

One of the biggest challenges is sustainability. Consumers are becoming increasingly environmentally conscious, and they expect businesses to operate in a responsible and sustainable manner. This means reducing waste, minimizing carbon footprints, and sourcing materials ethically. Companies that prioritize sustainability not only contribute to a better planet but also build stronger relationships with their customers.

Supply Chain Trends to Watch

1. Reshoring and Nearshoring

With the rise of global trade tensions and supply chain disruptions, many businesses are reconsidering their sourcing strategies. Reshoring, or bringing production back to the home country, and nearshoring, or moving production to neighboring countries, are becoming popular alternatives to offshoring. These strategies can reduce dependency on foreign markets and improve supply chain resilience.

2. E-commerce Boom

The rapid growth of e-commerce has transformed the way consumers shop and how businesses operate. Online retail requires a different approach to supply chain management, with a focus on speed, flexibility, and customer experience. Businesses must adapt to meet the demands of this fast-paced environment, investing in technology and infrastructure to stay competitive.

3. Circular Economy

The concept of a circular economy is gaining traction as businesses look for ways to reduce waste and promote sustainability. In a circular economy, products are designed to be reused, recycled, or repurposed at the end of their lifecycle. This approach not only benefits the environment but also creates new business opportunities and revenue streams.

How Supply Impacts Businesses and Consumers

Supply doesn’t just affect businesses; it also has a significant impact on consumers. When supply chains are efficient and well-managed, consumers benefit from lower prices, faster delivery times, and a wider range of products. Conversely, supply chain disruptions can lead to higher prices, longer wait times, and reduced availability of goods. That’s why it’s crucial for businesses to prioritize supply chain optimization and resilience.

For businesses, a strong supply system can be a competitive advantage. It can help them differentiate themselves from competitors, attract and retain customers, and drive growth. But it’s not just about having a robust supply chain; it’s about continuously improving and innovating to meet changing market demands.

Strategies for Building a Resilient Supply Chain

1. Diversify Suppliers

Reliance on a single supplier can be risky, especially in today’s volatile market. By diversifying suppliers, businesses can reduce dependency and improve flexibility. This might involve working with multiple suppliers in different regions or exploring alternative sourcing options.

2. Invest in Technology

Technology is the key to building a resilient supply chain. Whether it’s adopting IoT devices, implementing AI solutions, or utilizing blockchain, investing in the right technology can enhance visibility, efficiency, and adaptability. It can also help businesses respond quickly to disruptions and changes in demand.

3. Foster Strong Relationships

Building strong relationships with suppliers, partners, and customers is essential for supply chain success. Communication, collaboration, and trust are the cornerstones of these relationships. By working together, businesses can create a more resilient and agile supply chain that can withstand challenges and seize opportunities.

The Future of Supply

Looking ahead, the future of supply is bright but complex. As technology continues to evolve and consumer expectations shift, businesses must adapt and innovate to stay ahead. This might involve embracing new technologies, adopting sustainable practices, and rethinking traditional supply chain models. The businesses that succeed will be those that prioritize flexibility, efficiency, and customer-centricity.

So, whether you’re a seasoned supply chain professional or a curious consumer, the world of supply is full of opportunities and challenges. By understanding the key components, staying informed about trends, and implementing best practices, you can navigate this dynamic landscape and achieve success.

Conclusion

In conclusion, supply is more than just a concept; it’s a vital component of modern business operations. From raw materials to finished products, every step in the supply chain plays a crucial role in delivering value to customers. By embracing technology, fostering strong relationships, and prioritizing sustainability, businesses can build resilient supply chains that meet the demands of today’s market.

So, what’s next? We invite you to join the conversation. Share your thoughts, ask questions, and explore other articles on our site. Together, we can unlock the potential of supply and shape the future of global trade. Remember, the supply chain is only as strong as its weakest link, so let’s work together to strengthen every part of it. Cheers to a brighter, more connected future!

Table of Contents

- What Exactly is Supply?

- Key Components of Supply

- Understanding Supply Chain Management

- Technological Advancements in Supply

- Challenges in Supply Chain Operations

- Supply Chain Trends to Watch

- How Supply Impacts Businesses and Consumers

- Strategies for Building a Resilient Supply Chain

- The Future of Supply

- Conclusion

Kinsey Schofield Husband: The Inside Story You've Been Waiting For!

Kevin Beets Wife: The Untold Story You Didn’t Know You Needed

Unlock The Secrets Of Buscar Kid CCTV Mom: The Ultimate Guide

What Is Supply Chain Management? Definition And Benefits, 60 OFF

Supply Chain Management Nortech

What is Supply Chain 4.0